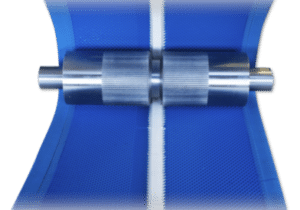

Each belt exhibits slightly different tracking characteristics due to the nature of the finger splice. Some belts may tend to run to the left while others tend to run to the right. As a belt moves to one side of a crowned pulley, the contact forces on that side of the pulley increase while the forces on the opposite side decrease. This forces the belt back toward the center of the pulley.

The alternative method — tracking via a lateral guide commonly called a “v-guide” — is not recommended by belt manufacturers. Habasit’s Fabric Conveyor Belts Engineering Guide (PDF link) states “Because of the relatively high production costs and their limited effectiveness, guiding profiles are not recommended as a general belt tracking measure.”

V-guides are recommended only in applications where lateral forces are placed on the belt due to products entering or exiting the belt from the sides of the conveyor. QC Conveyors’ Automation Series Conveyors can be equipped with v-guides in these applications. HydroClean Series Conveyors use v-guides in addition to crowned pulleys in all applications due to the varying frictional forces that can be imparted by a partially wet frame.