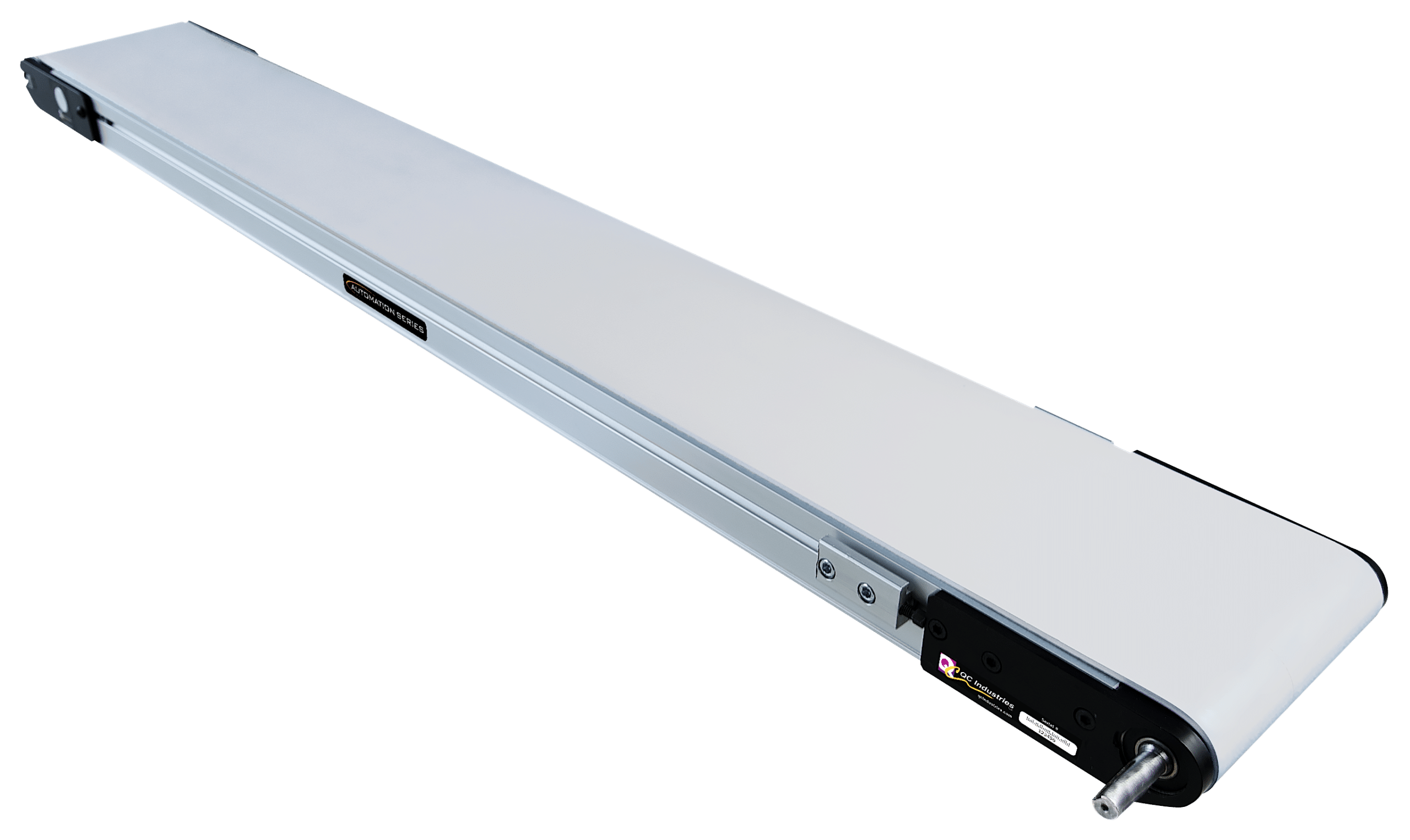

Versatile conveyor built on a rigid aluminum frame featuring tee slots for rapid accessory mounting.

2", 3", 4", 5", 6", 8", 10", 12", 18", 21", 24"

Up to 20'

Up to 120 lbs.

Up to 400 fpm

1.95"

Metric

Box Frame Construction for Rigidity

The frame is the backbone of the conveyor. A sturdy frame helps to ensure positive tracking throughout the life of the conveyor. That’s why we designed ours with a box-frame construction that resists both latitudinal and longitudinal deflections. Conveyors 18” and wider feature a rigid aluminum/steel frame.

More Information →

Ensures Accurate Tracking in Most Applications

On any conveyor, the belt pulls to the longest point on the conveyor. By using a crowned pulley — that’s higher in the center than at the ends — we’re able to ensure proper tracking in most applications without the use of a v-guide. The straight knurling provides positive traction, but allows the belt to float slightly from side to side without damage.

Flips up at the push of a button

Tension Release Tails flip up at the push of a button to relieve tension on the belt. This makes it easy to clean under the belt. A gentle push locks the tail back into place with tension and tracking setting retained.

More Information →

Proper tracking for demanding applications

All Automation Series conveyors support optional v-guide belting, which works to keep the belt centered in applications with side loading/exiting or reversing.

More Information →

Ideal for Transferring Small Products

Optional nosebar tails allow for transfers of small products between conveyors. The tighter 11mm radius of the pulley reduces the gap between pulleys.

More Information →

Backlights are used in a wide variety of machine vision applications to provide contrast for part inspection or robot orientation. The contrast from the backlight allows for better resolution from the vision system than reflective lighting can provide.

More Information →

Configure and quote conveyors 24 hours a day using our online Conveyor Configurator. An intelligent assistant uses engineer-developed rules to make sure all your components — including gearmotors, stands, and sides/guides — work together properly.

When you order a flat belt conveyor from us, we will build it to the size you need and ship with the industry’s shortest lead times. This includes all our most popular conveyor models — including our AS40 conveyors — when you order them with one of our most commonly-requested belt options (below). Conveyors with cleated and/or v-guide belts are available in seven days. Look for the Quick Ship icon in our Conveyor Configurator to find belt selections available with short lead times!

We are proud to stand behind the conveyors we build for five years. We’ll even double our warranty to 10 years when you register your conveyor at qcconveyors.com/serial.This warranty – the best in the industry – demonstrates our commitment to quality in every product we sell.

Our conveyors are designed to withstand the demands placed on them in modern industrial applications. Each conveyor is rigorously tested before leaving our factory to ensure quality.

Please see the full warranty details for more information.

Versatile conveyor built on a rigid aluminum frame featuring tee slots for rapid accessory mounting.

2", 3", 4", 5", 6", 8", 10", 12", 18", 21", 24"

Up to 20'

Up to 120 lbs.

Up to 400 fpm

1.95"

Metric

Plastics

Printing

Pharmacy & Medical

Robotics

Packaging

Material Handling

Marking & Coding

Automotive

Assembly

Automation

Robotiq recently highlighted this case study, where their robotic palletizing solution helped Chicago’s Napco Brands …

The key to meeting the five-day lead times of our Quick Shipping program is our …

Conveyor belts are, in general, designed to last a long time. There are some actions …

By submitting this information,

you are agreeing to our Privacy Policy.

4057 Clough Woods Drive,

4057 Clough Woods Drive, 4057 Clough Woods Drive,

4057 Clough Woods Drive,Phone: 513–753–6000

California Transparency in Supply Chains Act Disclosure

© Copyright 2024, QC Conveyors. All rights reserved.