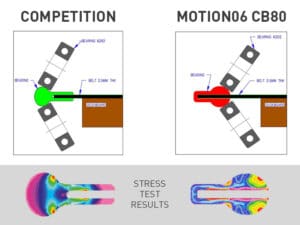

For tensioning, rollers installed inside the conveyor frame engage a bead on the outer edge of the belt. Motion06 uses beading that’s split longitudinally and encapsulates the edge of the belt. It is bonded then sewn into place. This puts the pressure of the rollers on the wide head of the beading, squeezing the edges of the belt in the process.

Competing conveyors reverse this, with sewn-on beading extending from the edge of the conveyor. Even when adjusted properly (which is difficult to accomplish), this puts a lot of pressure on the narrow neck of the beading and becomes a common source of breakage.

CB80 Curved Belt Conveyors are available as part of QC Conveyors’ Automation Series. A selection of sizes and angles are in stock for quick shipping.