Like our Flextrac Series conveyors, their supports are constructed from common components that can be configured in infinite ways. From stands designed to mount a single conveyor to the floor to supports meant to hang multiple conveyors from the ceiling, a wide variety of options are available to fit any application. Below are some of the most common configurations.

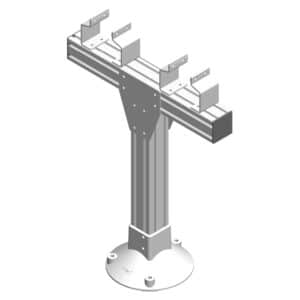

Type B1: This is the most common type of support — a single post with brackets that support a single conveyor. Once lagged to the floor, these are incredibly sturdy.

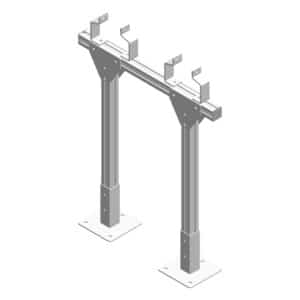

Type B2: These supports feature single post with a bar across the top used for mounting multiple conveyors in parallel.

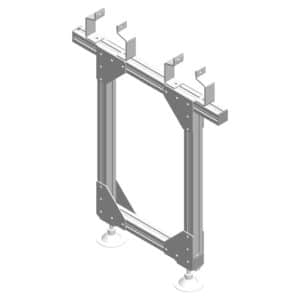

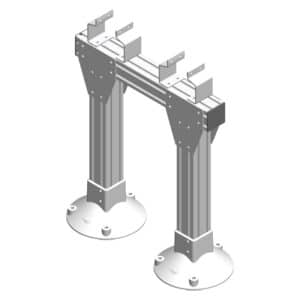

Type B3: For applications that aren’t lagged to the floor, these supports provide a sturdier base. They include leveling feet to offer additional adjustment.

Type B4: These supports provide a second option for non-lagged applications.

Type B5: Very similar to type B4, these supports use a thicker post that supports heavier loads and heavier conveyors.

Type B6: These supports feature a single post with conveyor frames cantilevered off both sides. They are typically used in alpine conveyors and the brackets are sized to accomodate the separation created by a wheel bend.

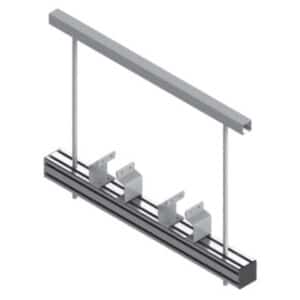

Type B7: To save space at floor level, conveyors are often hung from the ceiling. These supports provide a method for hanging them using rods and cross bars. We strongly recommend consulting a rigging crew to determine the feasibility of such mounting.

Type B10: Another common request is mounting conveyors to a wall or other vertical surface. These support provide a right angle mounting arrangement to support such installations.

The supports represented here are some of the most common, but by no means are they all inclusive. Our Applications Engineering team can help to determine the right combination of components to support the conveyors in your application.